The Fractional Distillation Unit is a versatile and necessary tool used in the chemical industry to separate liquid solutions into their constituent parts. This sophisticated apparatus works on the principle of fractional distillation, which uses the differences in boiling points between the various compounds in the mixture. As the mixture is heated, the components with lower boiling points evaporate first and rise through a fractional column before condensing into liquid form. These condensed fractions are then collected, processed, or tested as required.

The Fractional Distillation Unit equipment has accurate temperature control mechanisms and efficient condensation systems to ensure flawless separation and maximum yield. Its applications include petroleum refining, medicine, and food preparation, all needing cleaning and separating liquids. The fractional distillation apparatus, with its durable design and consistent performance, contributes significantly to manufacturing high-quality products and scientific research advancement.

What is Fractional Distillation?

Fractional distillation is a process used to separate complex mixtures into their components. This method is particularly useful when the components have similar boiling points. Using a Fractional Distillation Unit can achieve a higher degree of separation and purity, making it an essential tool for various industries, including pharmaceuticals, petrochemicals, and research laboratories.

Working of Fractional Distillation Unit

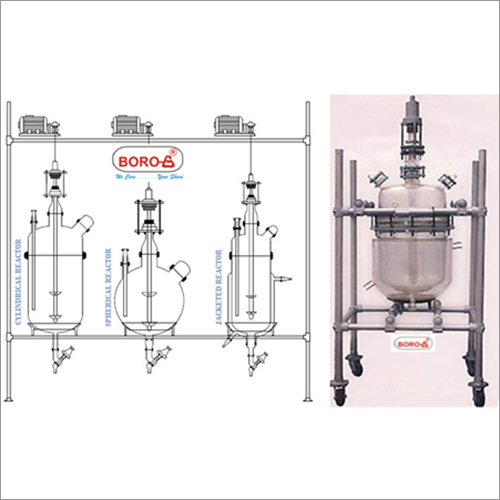

Fractional distillation is a compact batch-type unit featuring a re-boiler consisting of a vessel mounted in a heating bath with a packed column above. The vapors from the top are condensed and can be reflux as needed.

The top product is sub-cooled and collected in receivers, while the bottom product is drained from the re-boiler through a drain valve.

Fractional distillation units are available in vessel sizes of 20L, 50L, 100L, 200L, 300L, and 500L and may operate at both air pressure and full vacuum.